cam and tappet experiment

A standard steel ball of 6 mm diameter reciprocates on fixed disc 40 mm 40 mm 5 mm submerged in an oil bath under a normal load of 98 N. This table shows the change in effective duration at the valve from different valve-lash settings on a Comp Cams Xtreme Energy No.

Schematic Of A Cam Tappet Contact Configuration Download Scientific Diagram

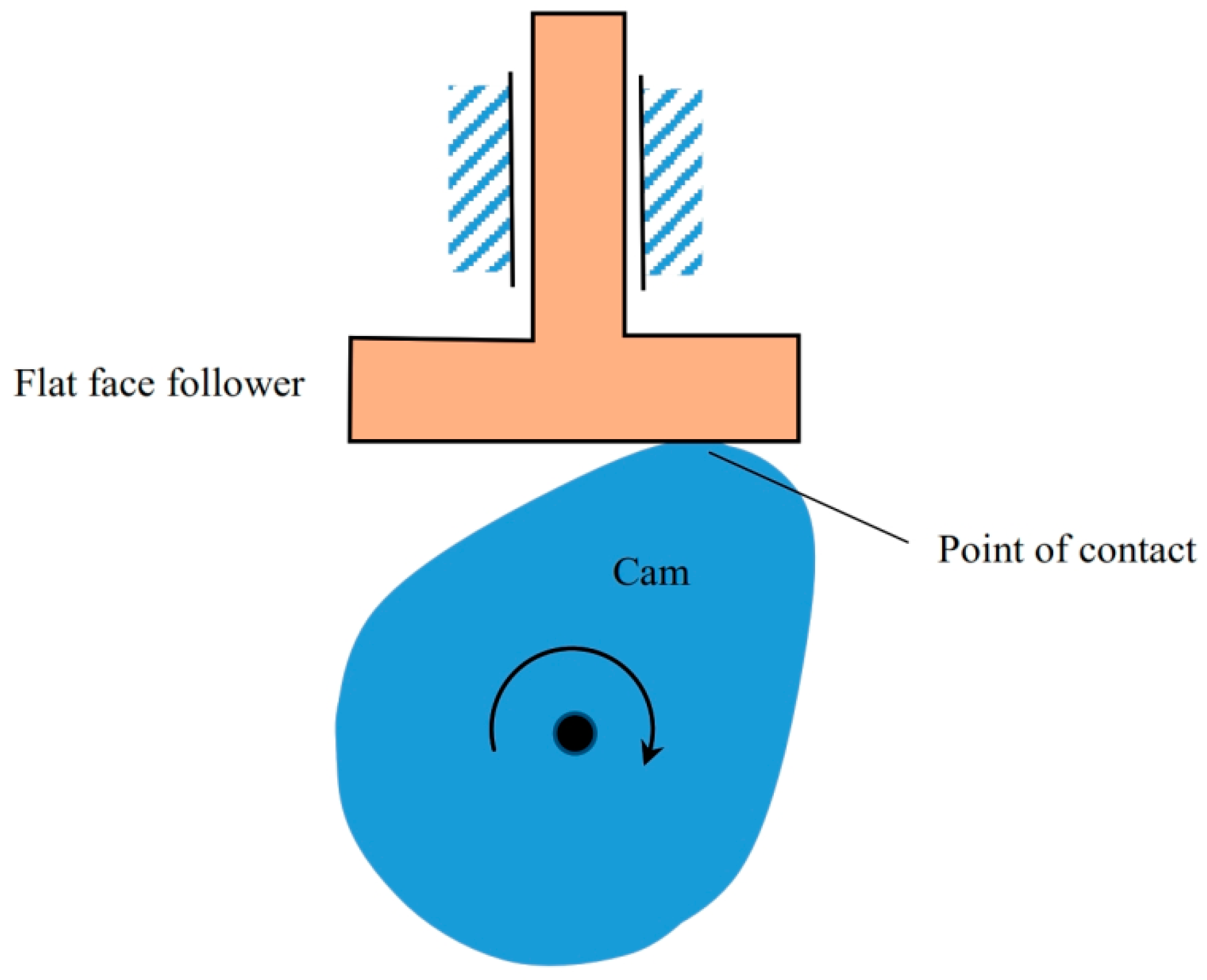

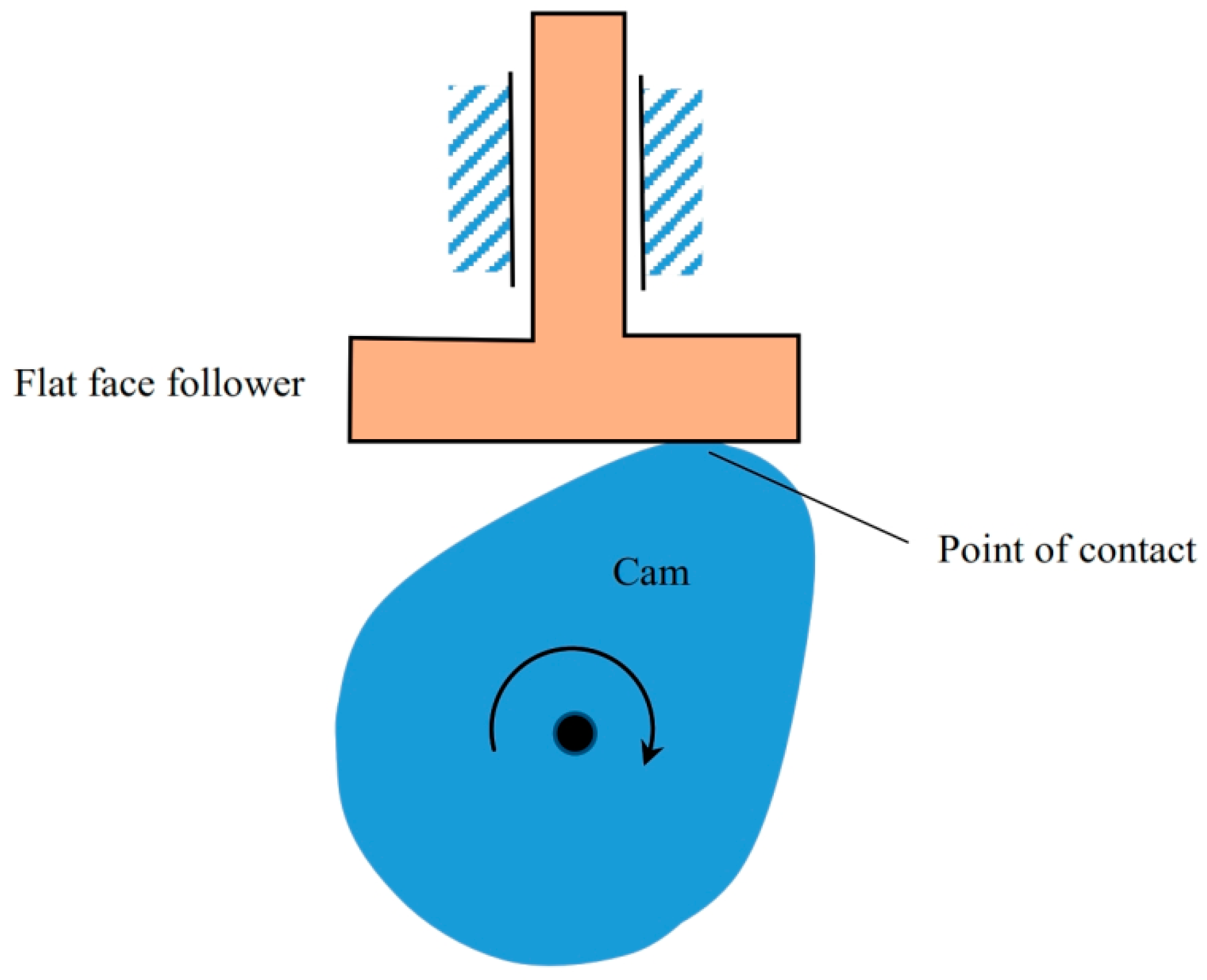

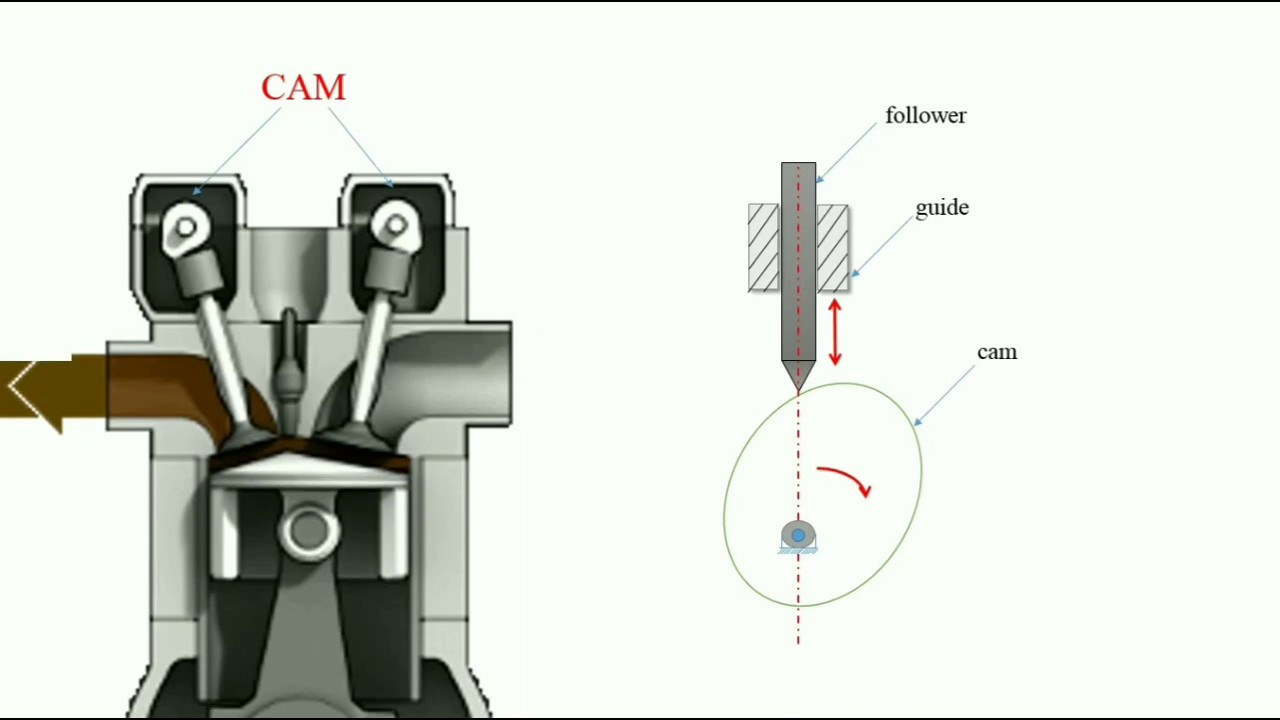

Follower inhibits the push and pulls of the Cam.

. Tappets commonly used by automotive engines are solid lifters hydraulic lifters and roller lifters. Day and Date experiment performed. This will draw a path on the graph paper.

The bulk temperature showed a mild effect on the wear characteristics of the cam and follower as it was increased from 75 C to 105 C whilst a substantial influence was found as the temperature was further increased to 120C. Under the lubrication regime friction chemical reaction was induced and the tribofilm partially covering the surfaces of the tappet inserts and the cam was advantageous to improve their antiwear property and fatigue life. Book an inclined plane and use the pencil as a slider use your hand as a guide.

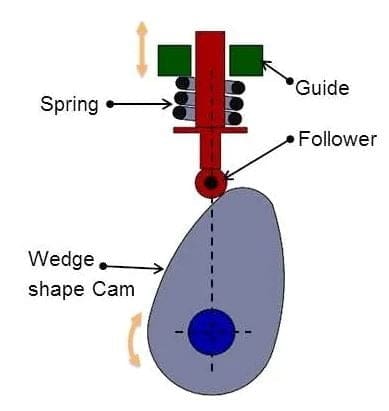

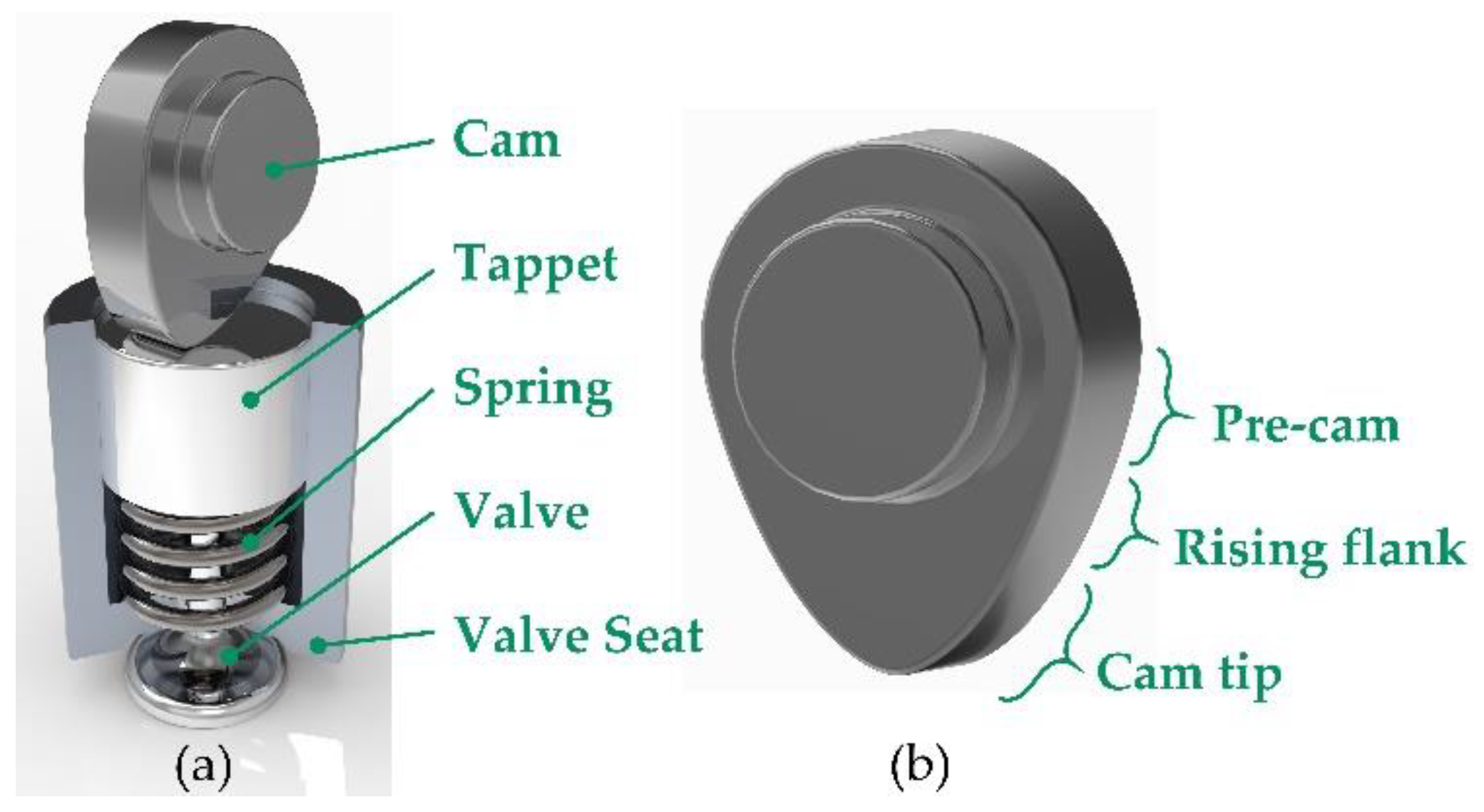

When you move the book smoothly upward what happens to It will be pushed up along the guide. In an internal combustion engine a tappet also called a valve lifter or cam follower is the component which converts the rotation of the camshaft into vertical motion which opens and closes the intake or exhaust valveThe types of valve lifters ie. Statement of Purpose Objective.

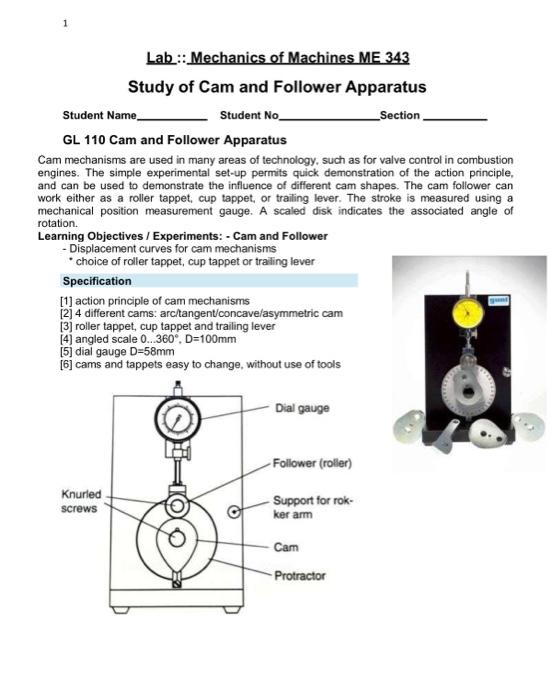

TEHL camtappet-contact of the valve train. Universiti Tenaga Nasional 2006 Mechanical Design and CAD Laboratory CAM AND TAPPET EXPERIMENT OBJECTIVE The objective of the experiment is to investigate tappet motion for several different cam profiles and to study the effect of different followers. The apparatus used is the cam and tappet apparatus with roller domed and flat followers equipped with dial indicator.

A tappet is a cam having some dwell period which controls the updown movement of heald shafts and the time of opening of the shed. This rotation of the tappet induces even wear all around the bottom surface of the tappet and increases the life of both the tappet and the cam lobe. The engine manufacturers use the most suitable materials lubrication additives and surface coatings to minimize friction in all the components of the engine.

The Follower rotates in an oscillating or circular arc. According to the Hertz theory the kinetic equation of the cam-tappet friction pair was established. Reduced friction results in less wear of critical engine components.

When you move the book smoothly upward what happens to It will be pushed up along the guide. Study on tappet shedding mechanism. - Investigate tappet motion for several different cam profiles and to see the effect of different followers.

Data For Convex cam. Data Observation and Results. In internal combustion engines cam and follower helps in the opening and the closing of the values.

Take a pencil and a book to do an experiment as shown above. Then the contact stress between the cam and the tappet was simulated by using the multi-body dynamics simulation software ADAMS respectively for the engine running at idling speed rated speed and over-speed condition. Flying off of the tappet took place which caused repeated impact forces between the interface of the tappet and the cam.

Tappet is a type of cam to which a rotary motion is given for the purpose of producing reciprocating motion in rods and levers by sliding contact. Tappets are generally used for heald shedding. A follower is used to transfer the motion to the required machine part.

The mechanism for Cam and the mechanism for Follower depend. Then the experiments were conducted with lubricating conditions for investigating the impact of lubricant on the contact of cam and tappet in valve train using HFRR. When the rod is to receive a series of lifts with intervals of rest and thus forms.

This paper aims to present a technique that has been developed to study the wear in the camshaft and tappet. The purpose of this experiment is to investigate tappet motion for several different cam profiles and the effect of using different followers. It assumes a 151 rocker arm.

Therefore tribological cambucket tappet component Stribeck tests were used to determine the friction behavior of ultrashort pulse laser fabricated microtextures and PVDPECVD deposited. Any sudden movement to the dial indicator stem was avoided. Tappetbore friction and torque at the camshaft were measured for a direct acting bucket tappet using a camtappet friction apparatus.

Asif Ahmed Safwan - 2127. Gear meshing the friction of the camtappet pair the centrifugal force of the cams and valve clearance are also considered. Tappetbore and camtappet friction torque and friction coefficient as a function of cam angle were derived from those measurements.

Fix a marker and a graph paper around the apparatus and give a complete revolution to the cam. Eventually the cam lobe and tappet wear in together such that the contact between them is a straight line. Have transformed one motion into another motion by a very simple This is the basic idea of a cam.

This cam profile is first modified for the minimum rubbing velocity between cam and follower. The design simulation of a four-dwell cam dynamic test rig to test dynamic properties is the main. The results showed that for the particular geometry tested tappetbore.

A follower is a mechanical component concerning which the Cam rotates in an oscillatory or circular motion. 3315 hydraulic-roller lobe profile. THEORY Introduction Cams are widely used in engine machine tools textile and packaging machines.

The camshaft rotational speed exceeding 2000 rpm. Tappet cam and wipers are names given indiscriminately to those irregular pieces of mechanism to which a rotary motion is given for the purpose of producing by sliding contact. Tappets are generally used for heald shedding.

Experiments on housing vibration and. The two knurled nuts were undo and the two washers were removed. The researchers are constantly.

Take a pencil and a book to do an experiment as shown above. Draw a semi-circle on the left side of the paper. The objective of the experiment is to investigate tappet motion for several cam profiles and to see the effect of different followers.

Have transformed one motion into another motion by a very simple This is the basic idea of a cam. Book an inclined plane and use the pencil as a slider use your hand as a guide. The wear characteristics were also examined.

At that point the oil film on the parts greatly decreases the wear rate and the cam and tappets can be expected to last well in. Divide into 8 equal parts. The objective of the experiment is to.

What Are Cam And Follower Types Working Terminology Application Notes Pdf

Cam And Follower Definition Types Working Principle And Applications Pdf Learn Mechanical

Cam And Follower Definition Types Working Principle And Applications Pdf Learn Mechanical

Examples Of Valve Train Configurations A Radial Actuation B Download Scientific Diagram

Tm 1315 Cam And Follower Apparatus Infinit Tech

Cam And Follower Definition Types Working Principle And Applications Pdf Learn Mechanical

Lubricants Free Full Text Lubrication Analyses Of Cam And Flat Faced Follower Html

Cam Tappet Contact Force Download Scientific Diagram

Lubricants Free Full Text Understanding Friction In Cam Tappet Contacts An Application Oriented Time Dependent Simulation Approach Considering Surface Asperities And Edge Effects Html

Cam Follower Mechanism Mechanical Kinematics Engineering Cam Gtu Youtube

Solved 1 Lab Mechanics Of Machines Me 343 Study Of Cam Chegg Com

Beat Up Mechanism In Weaving Weaving Shuttle Loom Motion

Pin By Eng Ahmed On Wave Flow Chart Chart Cone

The Motored Single Cam Rig A Photograph Of The Rig B 2d Schematic Download Scientific Diagram

Cam Design Calculation Of Torque Required By Cam Shaft Physics Forums